DRUG PREFORMULATION

DRUG PREFORMULATION

DATA INTEGRITY

GLOBAL COMPLIANCE

QUALITY ASSURANCE

DRUG PREFORMULATION PROCESS

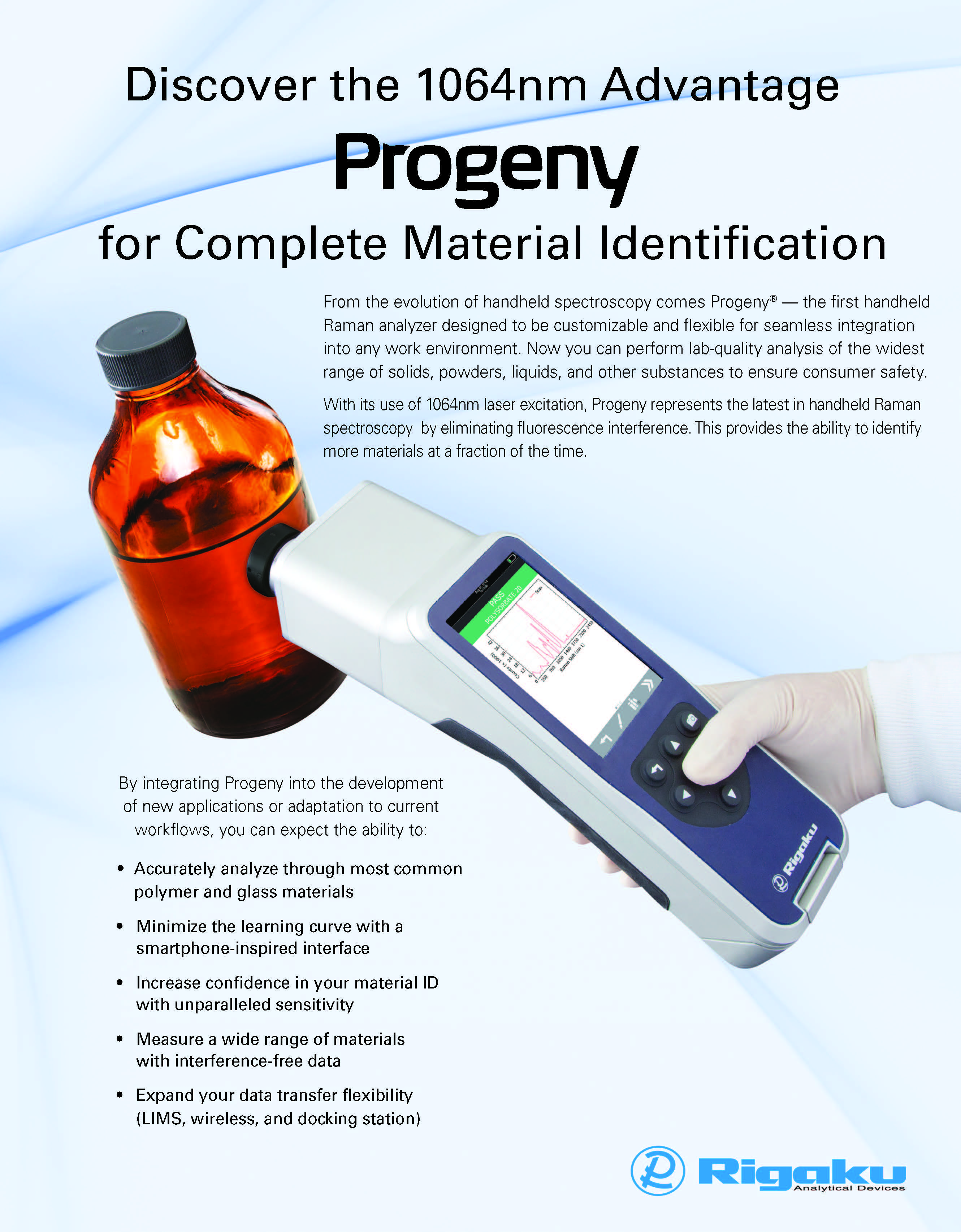

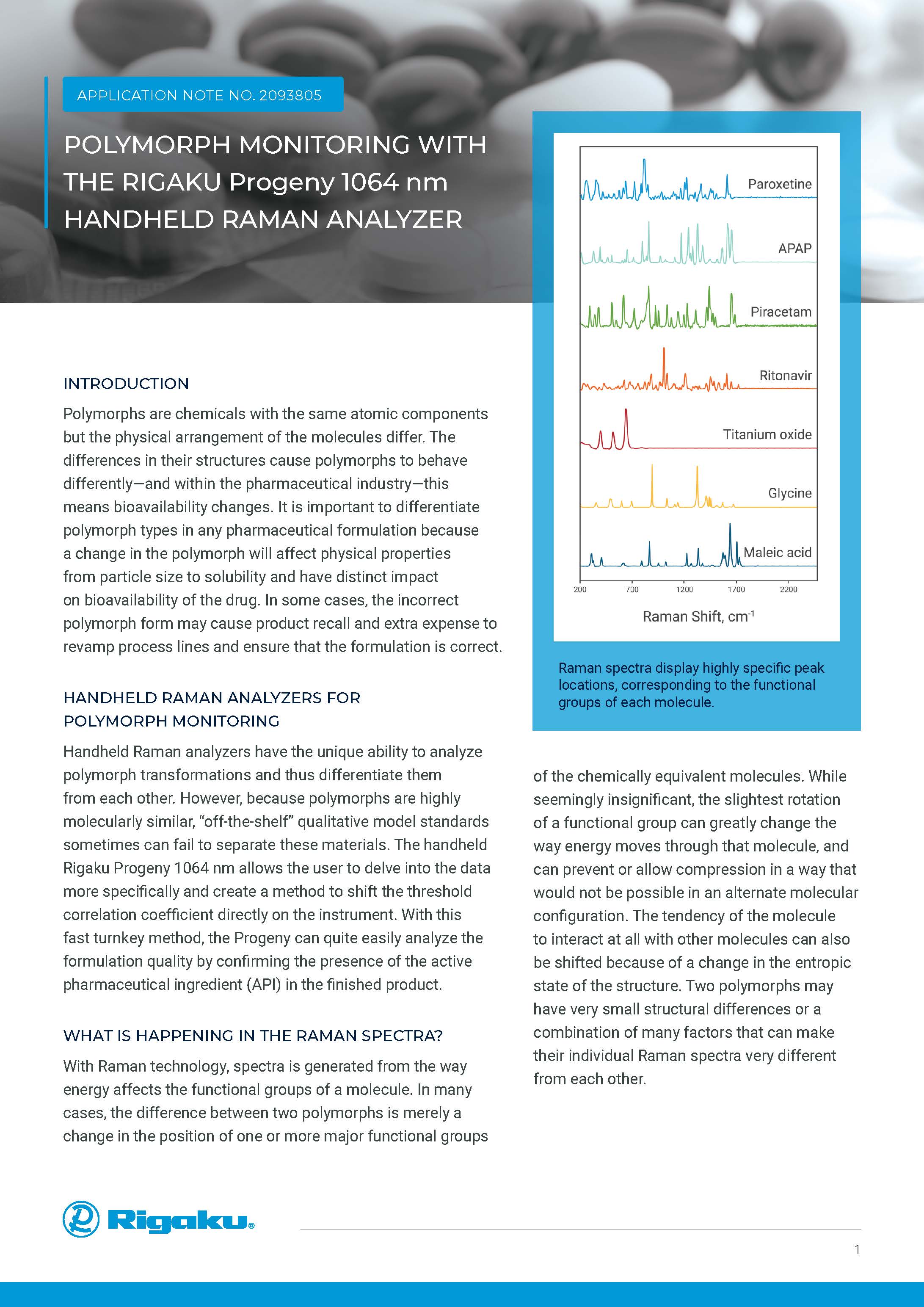

Once a lead New Molecular Entity (NME) has been identified during discovery, the screening and selection of solid forms is often a critical next step in the successful development of a new pharmaceutical product. Traditionally, solid form screening has focused on the isolation of the most stable crystalline form but as NMEs become more complex with challenging properties, alternative screening strategies are emerging. Different solid forms of an NME are referred to as polymorphs, which in the regulatory definition include different crystalline forms, amorphous forms and hydrates/solvates. Salt forms of NMEs with ionizable groups are considered to be a different molecular entities and may also be polymorphic in nature. Cocrystals and amorphous solid dispersions (ASD) offer alternate solid forms that can be utilized to improve critical attributes such as stability, solubility, and manufacturability.

During the investigation of different solid forms, analytical chemistry plays a vital role. Utilizing techniques such as X-ray Diffraction (XRD), Raman/IR spectroscopy and Thermal analysis (such as DSC) for structural characterization of the different solid forms.

In this early development stage, refinement of process chemistry and synthetic routes is a major component of ensuring purity and establishing appropriate manufacturing capability. Analytical chemistry again plays a significant role in optimizing process chemistry using elemental techniques like X-ray Fluorescence spectroscopy (XRF) and molecular techniques like Raman/IR spectroscopy to assay purity. The purity of the synthesized (or isolated) molecular entity will have a direct impact on the solid form landscape and crystalline forms are often utilized to help improve molecular purity, giving a synergistic relationship between process chemistry and solid form selection.

The drive to keep costs low in the early development stages, combined with the need to move swiftly through development and the high attrition rate of candidates, has sparked interest in a phase-appropriate solid form screening technique for small molecule candidates. Screening operations become more comprehensive as resources become available and technical needs alter in a phase-appropriate methodology, which is an iterative process. Limited screens are employed during early development to establish an appropriate solid form that would allow a speedy advance to the next milestone.

More material and resources become available later in development, after clinical proof-of-concept, and complete screening can be undertaken to locate all solid forms for intellectual property protection and determination of the best solid form for commercialization.

Many aspects of the discovery, design, development, and formulation processes rely on analytical methods to give structural information acquired by diffraction techniques, molecular information from spectroscopic techniques, elemental information from fluorescence techniques, and phase information determined by thermal techniques.

A DAY OF EDUCATION AND INSIGHTS FOR PHARMACEUTICAL PROFESSIONALS THROUGHOUT THE PRODUCT DEVELOPMENT LIFECYCLE

Pharmalytical Summit 2021 is a one-day virtual event exploring the technologies, analysis, and innovation that goes into bringing the pharmaceuticals allowing humanity to live longer, fuller, healthier lives.

The day features presentations and discussions with industry leaders and experts who share insights and education to help bring these life-changing products into the world.

Join us on May 26th, 2021 from 8 AM to 8 PM CDT.

RELATED APPLICATIONS

Polymorph Monitoring Using 1064 nm Handheld Raman

Powder X-ray Diffraction for Pharmaceuticals

Direct CNOX analysis of solid forms for confirmation of composition and determination of salts/stoichiometry, hydrates, and solvates by WD-XRF

The Use of Atomic Pair Distribution Function Analysis to Verify Molecular Structure for Amorphous and Non-Crystalline Systems

INDUSTRY-LEADING SUPPORT

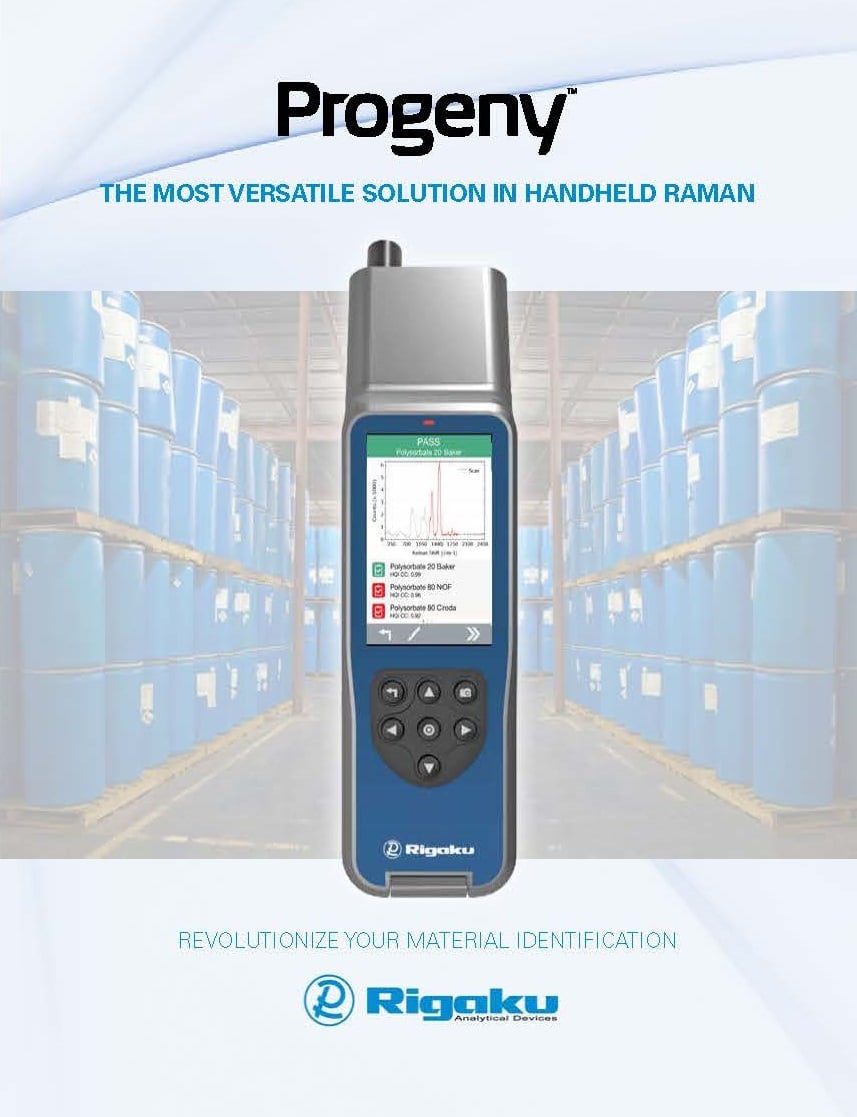

"We use Progeny at every point in our manufacturing."

"Another thing I like about Progeny is the software as it relates to data integrity, ALCOA and those type of principals that you’re operating under a GMP environment.”

“I came at this with very little analytical background…and I found the instrument really easy to use…”

"The fact that we can continue to add new materials to the library is a huge benefit and the device is now also being used to establish ID methods in new product ingredients."

MADE IN THE USA

FOCUSED CUSTOMER SUPPORT

RECOMMENDED PRODUCT

PROGENY HANDHELD 1064 nm Raman

Versatile Spectrometer for Raw Material Identification and Verification

LEARN MORECUTTING-EDGE TECHNOLOGY

HANDHELD 1064 nm RAMAN SPECTROSCOPY

FEATURES & BENEFITS

- NONDESTRUCTIVE

- ANALYZE SOLIDS, LIQUIDS, POWDERS, GELS, PASTES AND MORE

- SCAN THROUGH COLORED PACKAGING

- ANALYZE COLORED SUBSTANCES

- RESULTS < 1 MINUTE

- MINIMIZED FLUORESCENCE

HOW WE WORK WITH YOU

TRUSTED PARTNER

Based in Wilmington, Massachusetts, USA since 2011, Rigaku is a pioneer in handheld 1064 nm Raman and LIBS-based technology for materials analysis. With thousands of units in use globally, our portfolio offers the most versatile solution for use in safety and security against chemical threats, pharmaceutical manufacturing, and in the recycling and quality control of metal alloys.

We strive to deliver quality, reliability and engaged expertise to our customers. We are dedicated to continuous product development efforts to deliver mission-critical enhancements to performance and functionality, while delivering reliable and cost-effective solutions for results, anywhere.

Rigaku Analytical Devices is an ISO 9001:2015 certified facility.

RESOURCES

- BROCHURE

- SPECIFICATION SHEET

- APPLICATION NOTES

- FAST FACTS

- WHITE PAPERS

- CASE STUDIES

- ACCESSORIES

_Page_1.jpg)